Installation and use

◆ Pump should be installed horizontally should not erect, the body can not withstand the weight of the piping, pumps and piping system should maintain a good seal, no loose fasteners.

◆ Unscrew the top of the water pump bolts, adding liquid water not less than two-thirds of the volume of the pump, tighten the bolts.

◆ Should be checked before using the pump, the motor rotation flexibility, consistent with the direction of rotation of the motor turning mark, no jamming and abnormal sound.

◆ The motor starts, slowly open the discharge valve until the pump into the normal working state, then the discharge valve to the desired degree of opening.

◆ The pump is stopped before the work should be closed discharge valve, then close the suction pipe valve.

Precautions

◆ Due to the cooling and lubrication pump bearings is to rely on the media to be delivered, so the absolute prohibition of non-media operation, and should avoid operating without media blackout in the middle and then start work caused.

◆ If the transmission medium containing solid particles, before the pump inlet to add filter, such as those containing ferromagnetic particles, need to add a magnetic filter (The factory has a production belonging optional).

◆ The medium and its temperature should be conveyed in the pump material within the allowable range. Self-priming plastic magnetic pump use temperature <60 ℃, inlet pressure of not greater than 0.1MPa, the maximum working pressure of 0.6MPa;

◆ For transmission fluid is easy to precipitate crystalline media, after use should be promptly cleaned, drain the pump effusion within the net.

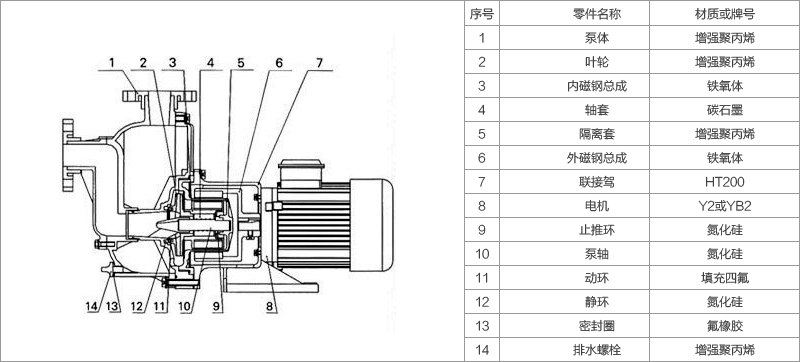

◆ Self-priming plastic magnetic pump after a long-running and found pump abnormality (noise, vibration intensifies), should wear dismantling the bearing ring and the end, if the gap between the bearing and the shaft of the impeller axial movement large, should be replaced and the axial bearing ring.