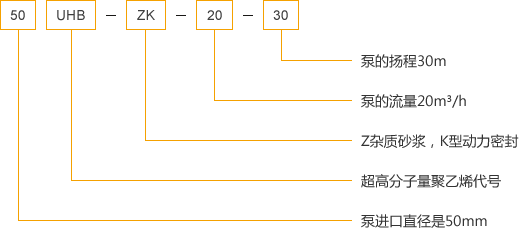

Overview

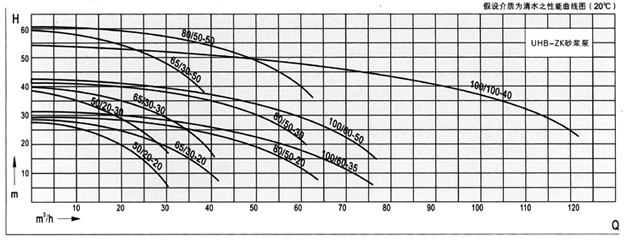

UHB-ZK series mortar pump cantilever single-stage, single-suction centrifugal pump flow components using steel liner ultra high molecular weight polyethylene structure, with strong corrosion resistance and excellent abrasion resistance. It can deliver 80% concentration of ulfuric acid, nitric acid and less than 50%, hydrochloric acid and other acids, alkalis, salt slurry, rare metals smelting industry corrosive mortar and food, the wine industry in a variety of mixed media.

Temperature: -20°C ~ 80°C

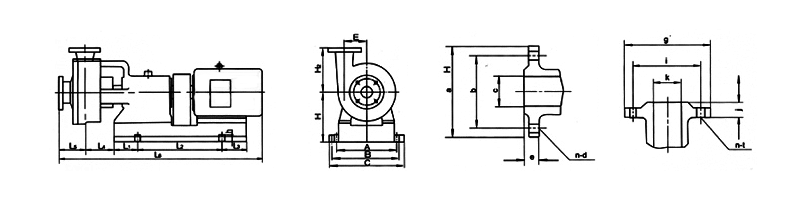

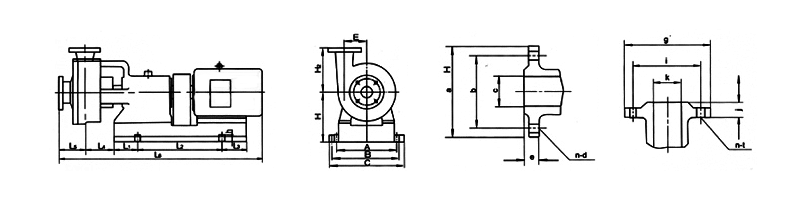

Appearance and installation size

Use and Maintenance

Disassembly and assembly:

◆ Commissioning should be preceded by hand plate dynamic coupling, check the rotation is flexible, turned teacher correct.

◆ Open the inlet valve supply fluid source, if there is no liquid injection height of the pump must first be filled with liquid.

◆ Connected to the shaft cooling water.

◆ Start the motor to the pump, and in time to open the outlet valve.

◆ Shutdown, turn off the outlet valve, and then cut off the power, stop the supply of cooling water at the seals.

Maintenance:

◆ Always check the pump and motor temperature rise, regular replacement of oil (fat) within the bearing plane, replacement of wearing parts.

◆ Not long-term shutdown, the pump should be cleaned flow channel, and cut off the power, winter Note antifreeze.

◆ To keep the pump clean to prevent the motor from moisture.

◆ Is strictly prohibited idling or reverse.